Kennametal

- Kennametal Inc. is USA based Company, which was established in 1938 in Latrobe, Pennsylvania by Philip McKenna, today almost 81 years old company.

- KIL-Bangalore is 100% subsidiary of Kennametal Inc. it’s Global leader in total tooling solutions as well as wear resistance solutions serving diverse Industries.

- Company generates 57% of revenue from metal working solutions & 43% of revenue from wear resistant solutions. It’s delivering productivity in the most demanding environments.

- Kennametal catering in metal cutting solution like Holemaking, Turning, Grooving, Milling & holding systems. Also provide solution for wear, heat & corrosion problems.

- Through our innovative solutions we deliver productivity, reliability & extended life in most demanding environments.

- Kennametal can cover all the segments like Aerospace , Transportation , General engineering , Earthworks , Energy & Process.

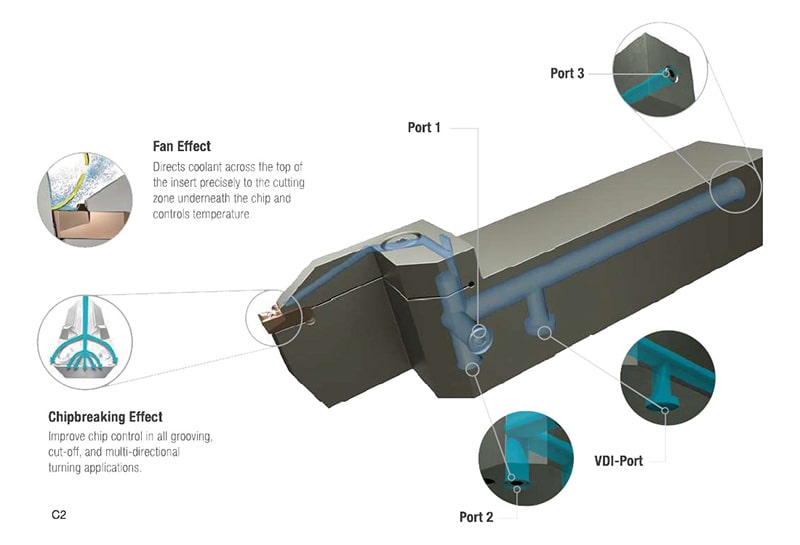

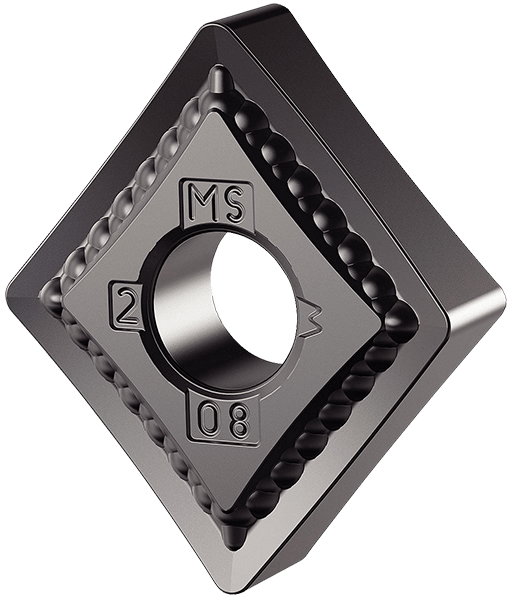

ISO Turning Inserts, Toolholders, and Boring Bars

Modern CNC machines and flexible production facilities require tools with application versatility. Kennametal high-performance inserts, toolholders, and boring bars are designed to handle any turning application. Whether you’re cutting steel or titanium, or doing light fi nishing or heavy roughing, we have the tooling solution to meet your needs.

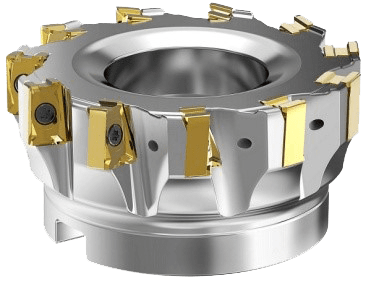

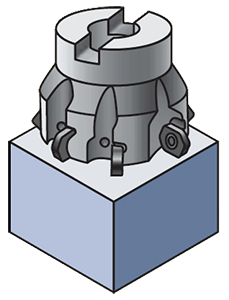

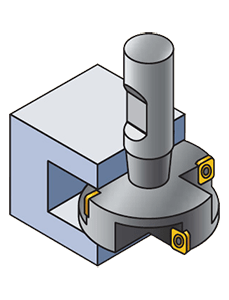

Indexable Milling

- Face Mills

- Shoulder Mills

- Slot Mills

- Copy Mills

For unsurpassed quality, value, and performance, you can trust Kennametal to provide the most comprehensive line of reliable metalcutting tools. Whatever your indexable milling product requirements, be assured that you will fi nd the appropriate solution in this all-inclusive, easy-to-use guide.

For every milling application, workpiece, or equipment need, we offer the best tools on the market, designed to reduce your machining time, provide superior surface finishes, and exceed your expectations!

Face Milling

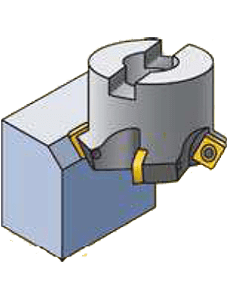

Chamfer Milling

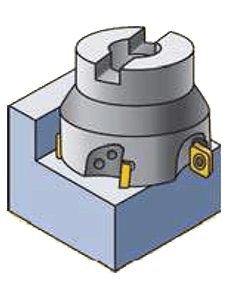

Shoulder Milling (End Milling)

Slotting Milling

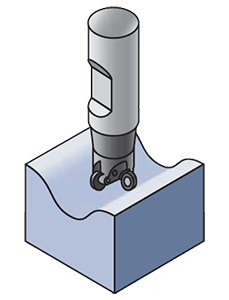

Copy Milling

Ceramic Milling

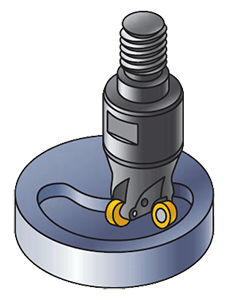

Thread Milling

Solid Carbide Milling

The SC Milling offers plunging, slotting, and profiling with long tool life on a wide range of workpiece materials. They are designed to provide high Metal Removal Rates (MRR) and achieve good surface quality at an excellent cost-benefi t ratio. A wide range of diameters and lengths are available with chamfered edge and ball nose as stocked standard.

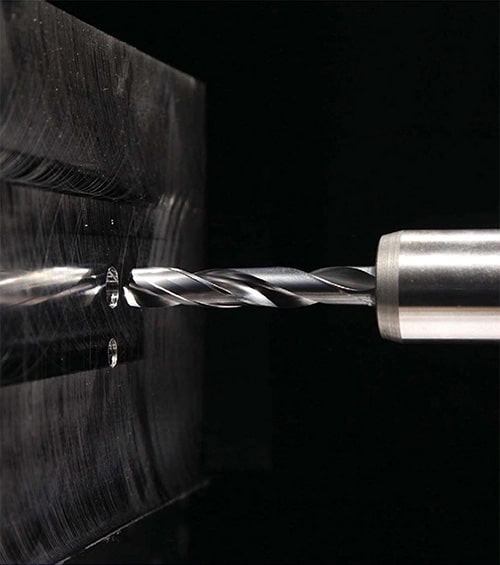

Holemaking

- Kennametal offers vast range of Holemaking tools. We assure for the quality tools and benchmarked product performance. Kennametal have Solid carbide drills, Modular drills, Indexable drills, Combination tools.

- Anyone can increase Productivity, Performance, Reduce cycle time and save machine hour rate with the use of Kennametal make Drills.

- We have a universal grade which are economical performer as well with material specific grades.

- We can offer you the best solution for your material starting from 1mm dia. to L/D=40.

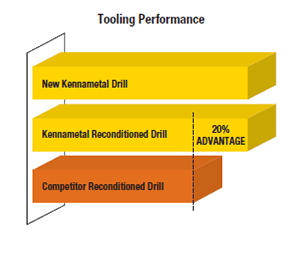

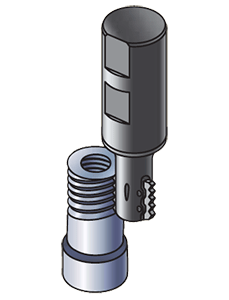

Reconditioning services

Our Reconditioning Services optimise the value of your metalcuting tools by providing like-new performance to tools on-hand. Reconditioning tools is smart for business and the environment. You save money, reduce inventory, and avoid material waste.

Customers purchase Kennametal tooling for its high performance. Why not continue receiving that same high perfomance after each reconditioning cycle? Kennametal can help you reduce tooling costs by more than 50% versus purchasing new tools. Taking advantage of our innovatie tooling designs provides even greater savings because the reconditioned tool continues to achieve the same like-new performance as the original purchase.