Metrology Fixtures

Metrology Fixtures

Using Renishaw fixtures can improve the throughput, reproducibility and accuracy of your inspection process with quick and repeatable fixturing set-ups.

Whether you are inspecting parts for aerospace, automotive, electronics, industrial or medical applications, Renishaw fixtures can provide a complete solution to your fixturing requirements and help to improve your inspection processes.

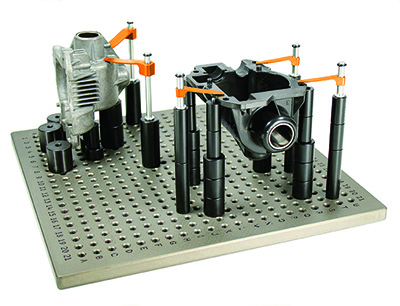

CMM Fixtures

The Renishaw CMM fixtures range includes a wide choice of standard size base plates and an extensive selection of components with M4, M6, M8 or 1/4-20 threaded fittings. Whether you are inspecting parts for aerospace, automotive, electronics, industrial or medical applications, Renishaw can provide a complete fixturing solution for any part regardless of its size, shape or material.

Fixturing solutions can be assembled very quickly to increase throughput and avoid delays in inspection. Each fixture plate has an alphanumeric grid pattern and each fixturing component has a clearly labelled part number, enabling easy documentation of the set-up. The same set-up can be quickly and accurately reproduced for subsequent inspections; this can be especially helpful when a single kit is used in multiple applications or where there are multiple users. Identical fixturing set-ups are important to improve the reproducibility and accuracy of inspection by removing variation from the process.

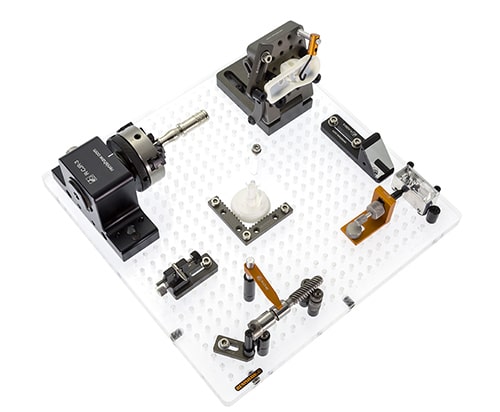

Vision fixtures

Renishaw’s vision fixtures offer two unique fixturing solutions designed to fit your specific vision system or multisensory machine

- QuickLoad™ corner (QLC)

- Interchangeable vision fixture (IVF)

Each system uses an acrylic base plate that allows for the use of backlighting for a clear view of the part on your vision system.