Zoller

ZOLLER – A family-owned enterprise starts into the future with the third generation

ZOLLER, founded as a mechanical workshop in 1945 by Alfred Zoller in the South of Germany, has developed into one of the world’s leading companies in innovative presetting and measuring machines as well as measuring, inspection, and management software for cutting tools.

As an independent, family-owned company, our work is shaped by long-term thinking and action. A pioneering spirit and a focus on innovation have been part of our corporate culture for almost 75 years, motivating us to develop solutions for better economic efficiency in machine production.

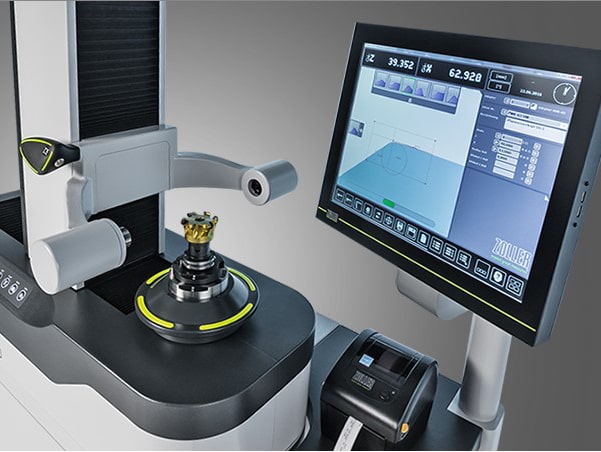

Our presetting and measuring machines are top performers around the world, impressing users with outstanding precision, low maintenance costs, and long service lives. In combination with smart software solutions, they help make production processes safer, faster, and more economical.

Presetting & Measuring

Modern CNC machine tools require exact tool geometry data in order to manufacture parts precisely. The tool presetter determines this tool data – outside the machine. This saves you a lot of setup time, because when you insert the tool, you immediately read in the tool data from the tool presetter. The data transfer is electronic and therefore completely error-free.

By determining the tool data outside the machine, you reduce the setup time to a minimum and the setup time is eliminated completely. This increases your productivity enormously!

Presetting and measuring machines from ZOLLER solve many challenges simultaneously. They minimize fitting times, prevent tool rejection and prevent machine crashes.

They are extremely easy, secure and convenient to use: as a result of the intuitive user interface with automatic tool-cutter identification; as a result of the single-hand operating device for each carriage alignment; and as a result of the membrane keypad for power-activated spindle clamping and spindle arresting.

Inspection & Measuring

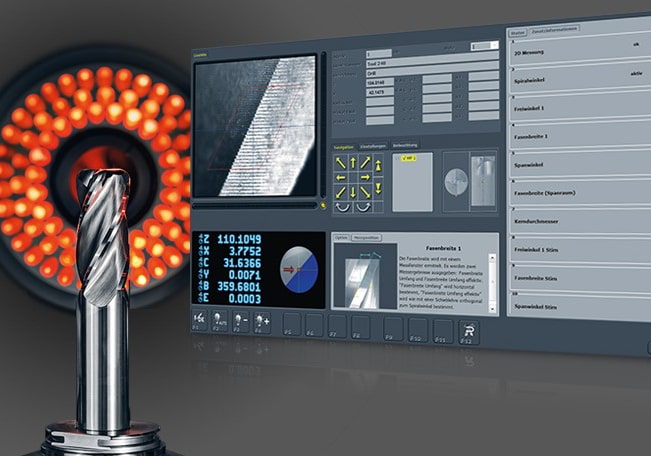

ZOLLER inspection measuring and machines work precisely, repeatable and independent of the user.

No matter whether you use standard or specialist tools, whether goods-in controls, production or end controls: There is the right measuring and inspection machine for each area of use. ZOLLER offers solutions from the simple and process-supporting inspection to the economic and fully automatic measuring of all tool parameters. For 100% perfect tools – always and everywhere.

Measuring is easy and safe with ZOLLER. With automatic solutions, tools are measured safely and accurately with a mouse click, user-independently and always the same. This applies to the inspection of complex geometries on threaded tools as much as to the high-precision measuring of cutting edge preparation or the recording of relevant data for the grinding program. All the results are seamlessly recorded and documented in detail.

Tool Management

It can be as simple as that – basic functions for efficient tool management

Complete tools, individual components and manage tooling sheets

Realistically Simulate and Plan

Interfaces from the TMS Tool Management Solutions for all common CAM and simulation systems

Smart storage cabinets – Tools at any time in the right place

Quick location of tools, test equipment and accessories

Data import made easy

Simple tool data import into TMS Tool Management Solutions

Order just-in-time

Secure optimum tool inventory, reduce tool and ordering costs

Automation

The Right Contact for Automation Solutions for Cutting Tools

ZOLLER offers the right solution for any task related to automated tool handling.

In an era where companies are facing a shortage of trained professional workers, automating everyday tasks – whether in the tool grinding shop or in tool preparation, delivery, and set up – can be the answer to this challenge.

Depending on requirements, the solution may be a closed system with additional modules, a complex automation concept, or collaborative robot support in the tool room.

You can achieve any degree of automation for your system based on your ZOLLER presetting and measuring machine with CNC drives ready for automation – and expand as needed. You can purchase solutions today for machines that have been on your shop floor for years. And you will still be able to do so into the future, guaranteed.